You should upgrade or use an alternative browser.

Arnnworx rear wheel bearing tool?

- Thread starter zcacogp

- Start date

Monkeythree

New member

I don't have the Arnworx tool but I do have a full professional set which covers every conceivable bearing size you are likely to come across. You are very welcome to borrow it if no-one comes up with an Arnworx for you but it weighs about 25kg so not really suitable for popping in a Jiffy bag!

Tom

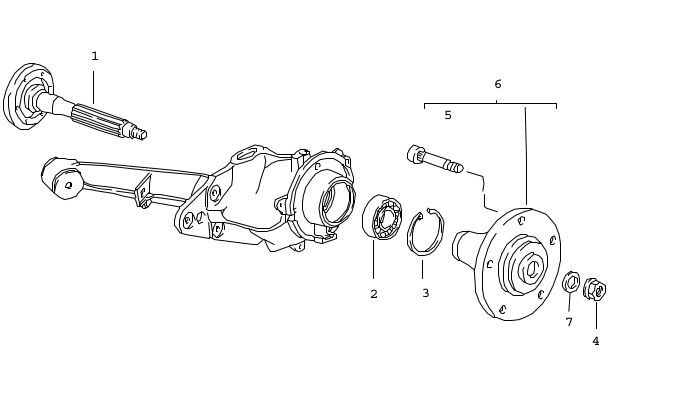

Thanks for the offer. The job I want to do is remove the inner rear axle, which is part 1 on this diagram.

I was assuming that I'd need to take the bearing out to do this but looking at things more closely I'm not so sure. What does the inner surface of the bearing support - does it support part 1 or part 6? Or, putting it another way, if the hub nut is removed then does part 1 tap fairly easily backwards or does it require significant force (which will probably destroy the bearing, meaning it needs to be changed)?

Thanks,

Oli.

I have a fairly long breaker bar and a socket of the right size so am willing to wade on in and have a go. The issue is what I will find when I am in there.

The problem is that I have the end of a snapped CV joint bolt stuck in the inner part (number 1) and need to take that part out to remove the remains of the bolt. How hard is it to get part number 1 out? If it's easy then I'll tackle it in a dull couple of hours. If it's hard then I'll need to trundle off to see a friend ....

Oli.

Monkeythree

New member

The drive shaft (1) sits in the bearing and once you have removed the hub (6), should just slide out without needing to remove the bearing. As Rob says, the hard part might be getting the hub nut off. If it's tight then I would weld up a plate with a long strong arm to bolt onto the hub and then the end of the arm can react against the ground while you put torque onto the nut.

If you are taking it all apart it might be worth changing the bearing anyway while you are in there?

I had a 3/4 drive socket with breaker bar an extension and the weight of the car resting on it and it still would not undo.

I also tried a professional Snap On nut gun without joy.

Eventually I had to cut both nuts off.....the car.

Once you get that nut off the rest just pulls apart easy.

Monkeythree

New member

Monkeythree

New member

edh

New member

Thanks for the answers. I've booked a day to go and see a practical friend to do the job and I'm thinking we may not tackle the wheel bearing after all, as it is not showing any problems. We need to take the back hub (Part 1 in the diagram) out so I plan to leave the front one in place so hopefully the bearing will remain in one piece.

Having said that, I can see an advantage in having an Arnnworx tool so thanks for your offer PSenior1 - I'll PM you.

Oli.

- Jack up car

- Remove driveshaft, tackling the CV bolts with stripped out heads along the way

- Remove wheel, tap out centre cap, replace wheel

- Put car on floor, insert socket through wheel with brakes on, undo outer nut

- Tap out centre axle

- Clean axle, inspect, drill out broken bolt stub

- Apply copaslip, reinsert axle in hub, replace nut, replace driveshaft

- Torque up nut, torque up wheelnuts, take for test drive

And that nut - was it tight or what! Well it may have been tight but it wasn't a big deal to get off. Using 3/4inch drive 32mm socket, 2 metre breaker bar (scaffold tube) and my sylphlike 8 stone* bulk on the end of it and it came undone gently and smoothly! I was expecting at least some swearing and a big 'bang' but there was nothing of the sort. I guess I should apologise to the assembled company for making a mountain out of a molehill but it really was no biggie!

Oli.

* - I was at the peak of my dieting success two days ago but things may have changed slightly since ....

Posts made and opinions expressed are those of the individual forum members

Use of the Forum is subject to the Terms and Conditions

Disclaimer

The opinions expressed on this site are not necessarily those of the Club, who shall have no liability in respect of them or the accuracy of the content. The Club assumes no responsibility for any effects arising from errors or omissions.

Porsche Club Great Britain gives no warranties, guarantees or assurances and makes no representations or recommendations regarding any goods or services advertised on this site. It is the responsibility of visitors to satisfy themselves that goods and/or services supplied by any advertiser are bona fide and in no instance can the Porsche Club Great Britain be held responsible.

When responding to advertisements please ensure that you satisfy yourself of any applicable call charges on numbers not prefixed by usual "landline" STD Codes. Information can be obtained from the operator or the white pages. Before giving out ANY information regarding cars, or any other items for sale, please satisfy yourself that any potential purchaser is bona fide.

Directors of the Board of Porsche Club GB, Club Office Staff, Register Secretaries and Regional Organisers are often requested by Club members to provide information on matters connected with their cars and other matters referred to in the Club Rules. Such information, advice and assistance provided by such persons is given in good faith and is based on the personal experience and knowledge of the individual concerned.

Neither Porsche Club GB, nor any of the aforementioned, shall be under any liability in respect of any such information, advice or assistance given to members. Members are advised to consult qualified specialists for information, advice and assistance on matters connected with their cars at all times.