Steve Brookes

Moderator

I've just fitted new rear brake discs to the car. This is the second time I've done these but decided that this time round I would replace the handbrake shoes which were still original. So I thought I would take a few photos and share my experience.

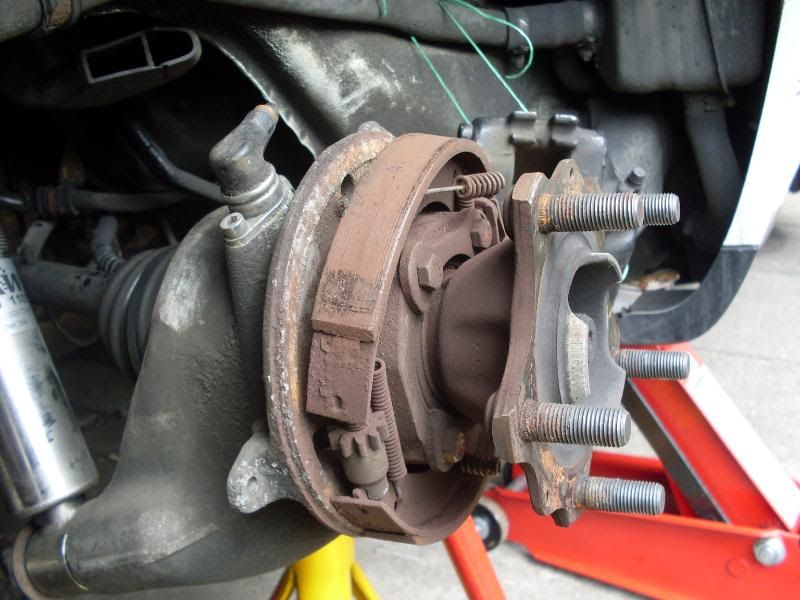

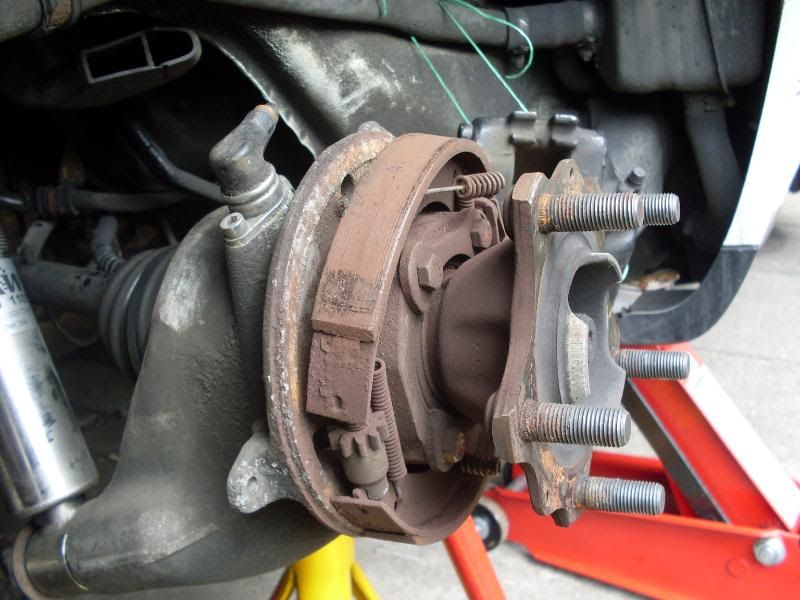

Here are the old shoes still in place after taking off a disc. First you need to compress the two retaining springs that secure the shoes to the hub and pull them out. You can see that I've already released the top one in the pic:

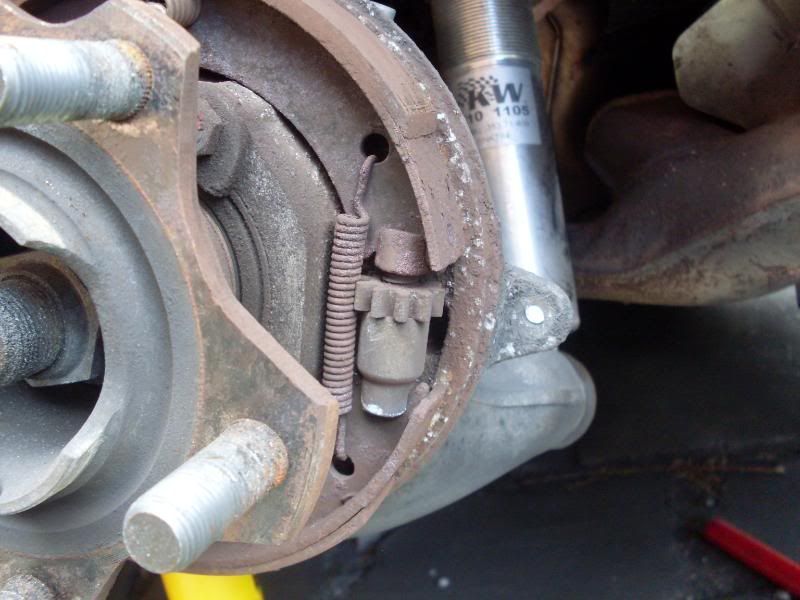

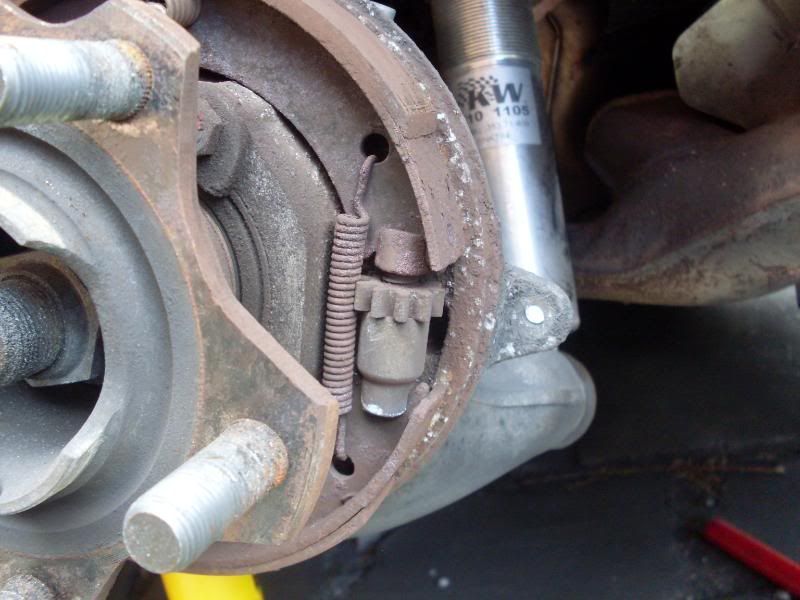

Next wind in the star adjuster all the way to release the tension from the two longer springs. The pic below shows the star adjuster on the other side after winding it in:

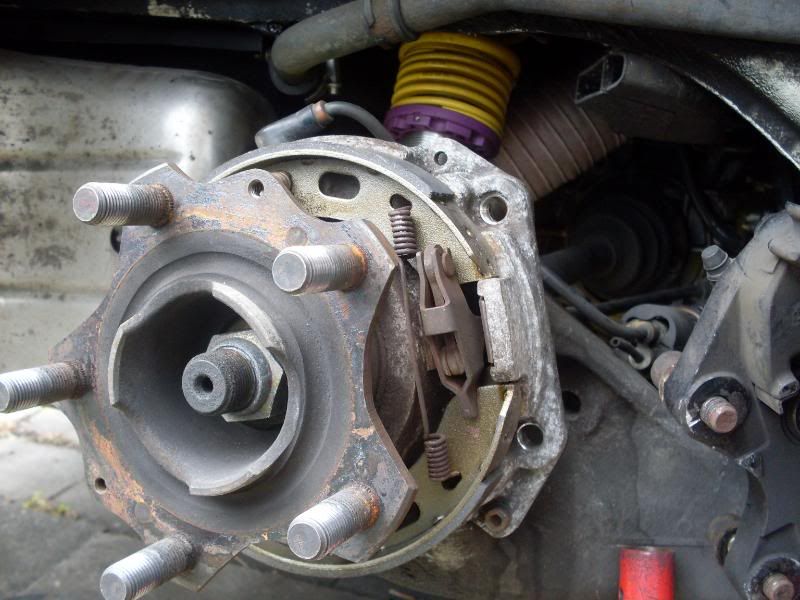

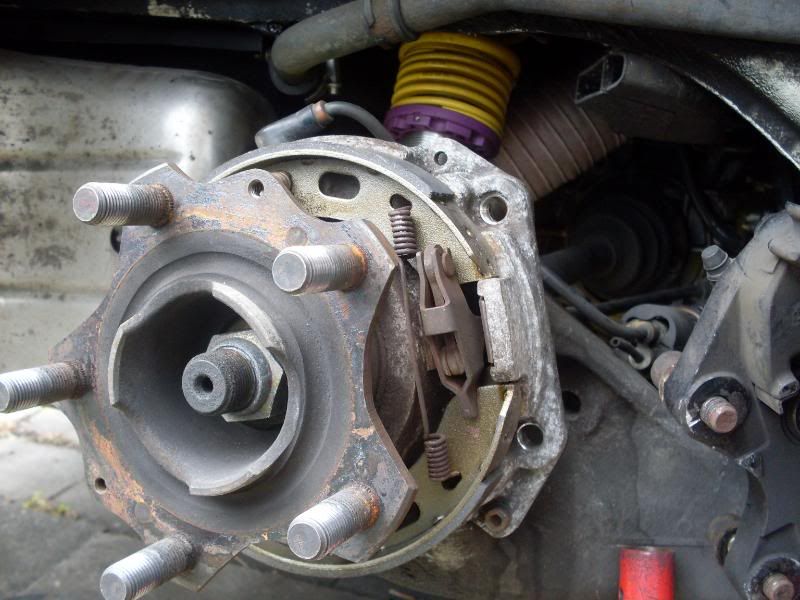

Now you can lever the shoes out of the recesses in the star connector and pull them off. But take note of the orientation of the lever mechanism on the other side of the hub because it will likely fall apart as you remove the shoes. The pic below shows the mechanism:

The pic below shows the old and new shoes (these are made by Pagid and are now the same as those used on the boxster and 996). Note that the wide notches connect to the star adjuster and the small notches to the lever mechanism (still on the hub):

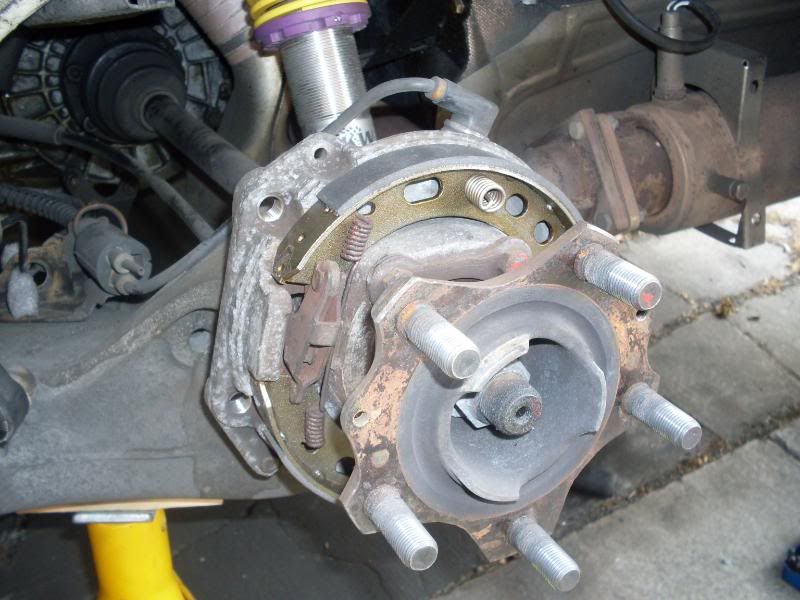

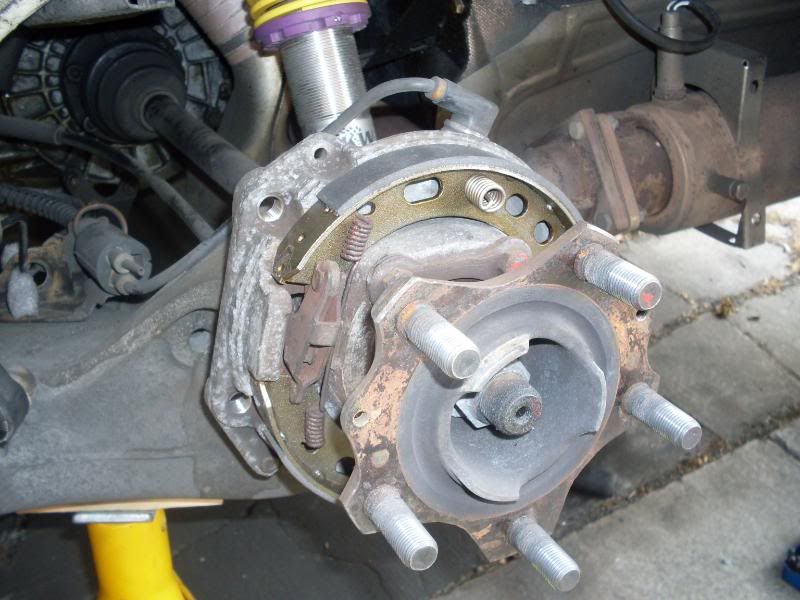

Fitting the new shoes is a fiddly process of lining up the small notches with the lever mechanism and attaching the 'double spring', then fit the single spring on the other side and slide/lever in the star adjuster. Finally, put the two retaining springs back in. I also decided to put copper slip on the star adjuster threads and on all the springs. The pic below shows the new shoes fitted:

Wind out the star adjuster until the new disc won't go back on and then wind it in four clicks and you'll have just about the right clearance. Put the disc on and check it spins freely without rubbing and that you can't move it when you try the handbrake. Pic of a new disc fitted:

Pic of my old discs after 3 years use and quite a few track days. They're starting to break up on the inside faces:

For anyone who hasn't changed their own rear discs before, make sure you have the right tools. In particular you need a long 10 mm allen bit to access the bottom caliper bolt through the trailing arm. The bolts are torqued to 85 nm so they're pretty hard to undo and a short breaker bar comes in handy. I put new caliper bolts in while I was in there.

Here are the old shoes still in place after taking off a disc. First you need to compress the two retaining springs that secure the shoes to the hub and pull them out. You can see that I've already released the top one in the pic:

Next wind in the star adjuster all the way to release the tension from the two longer springs. The pic below shows the star adjuster on the other side after winding it in:

Now you can lever the shoes out of the recesses in the star connector and pull them off. But take note of the orientation of the lever mechanism on the other side of the hub because it will likely fall apart as you remove the shoes. The pic below shows the mechanism:

The pic below shows the old and new shoes (these are made by Pagid and are now the same as those used on the boxster and 996). Note that the wide notches connect to the star adjuster and the small notches to the lever mechanism (still on the hub):

Fitting the new shoes is a fiddly process of lining up the small notches with the lever mechanism and attaching the 'double spring', then fit the single spring on the other side and slide/lever in the star adjuster. Finally, put the two retaining springs back in. I also decided to put copper slip on the star adjuster threads and on all the springs. The pic below shows the new shoes fitted:

Wind out the star adjuster until the new disc won't go back on and then wind it in four clicks and you'll have just about the right clearance. Put the disc on and check it spins freely without rubbing and that you can't move it when you try the handbrake. Pic of a new disc fitted:

Pic of my old discs after 3 years use and quite a few track days. They're starting to break up on the inside faces:

For anyone who hasn't changed their own rear discs before, make sure you have the right tools. In particular you need a long 10 mm allen bit to access the bottom caliper bolt through the trailing arm. The bolts are torqued to 85 nm so they're pretty hard to undo and a short breaker bar comes in handy. I put new caliper bolts in while I was in there.