chriscoates81

New member

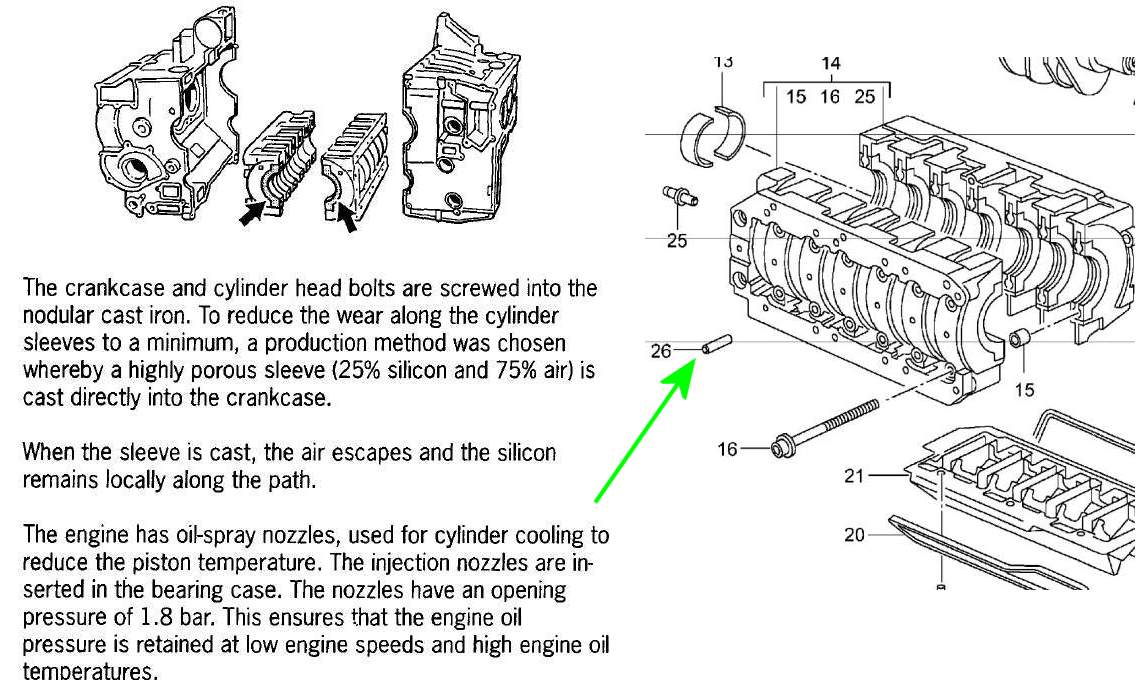

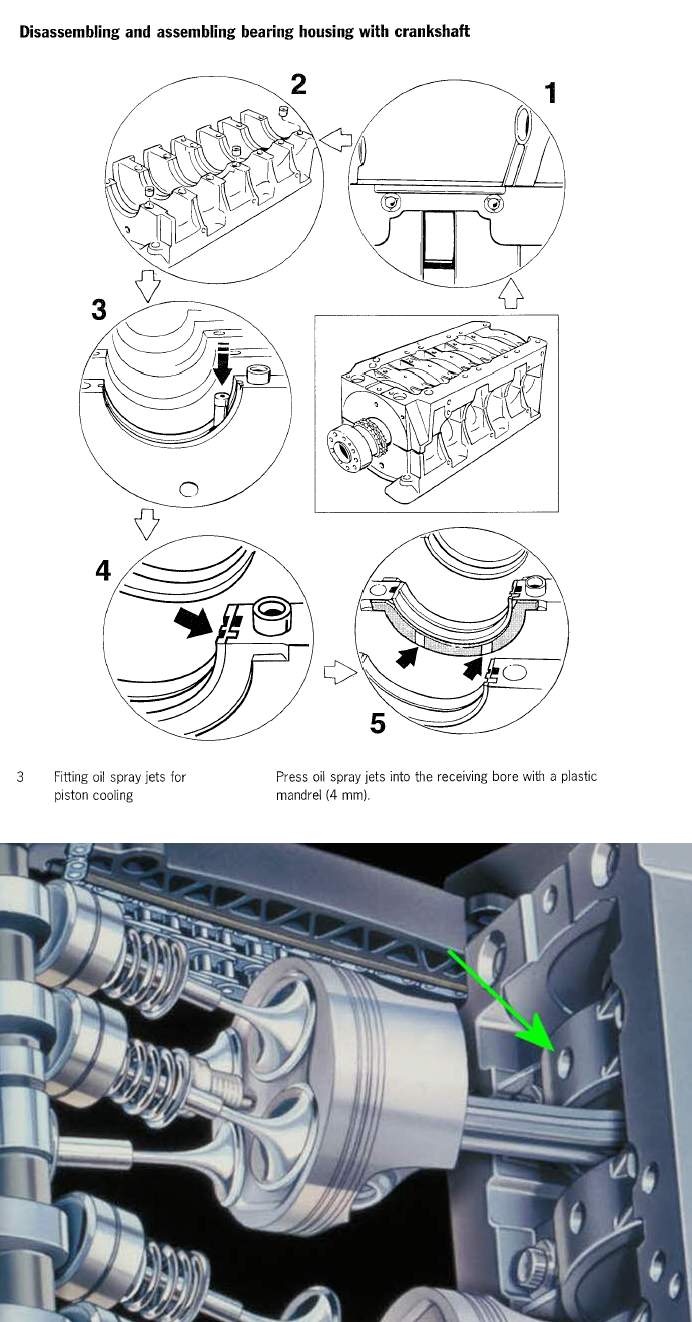

Hi guys, sorry if the title is a bit confusing but i think thats what the part is called. Anyway i took my car in for its service on saturday and when the mechanic removed the oil filter he mentioned that it looked like one of the oil jet sprays had snapped off. Heres a picture of the part i mean,

This is from a focus but it has the jets in each cylinder. Is it a big issue if one of these has come off, just to clarify it looks like the tube part has come off and the main bit is still attached. Ive had a look on several pictures of the 996 engine but i can't find these bits anywhere. Is it an engine out job to fix?

Cheers guys

Chris

This is from a focus but it has the jets in each cylinder. Is it a big issue if one of these has come off, just to clarify it looks like the tube part has come off and the main bit is still attached. Ive had a look on several pictures of the 996 engine but i can't find these bits anywhere. Is it an engine out job to fix?

Cheers guys

Chris