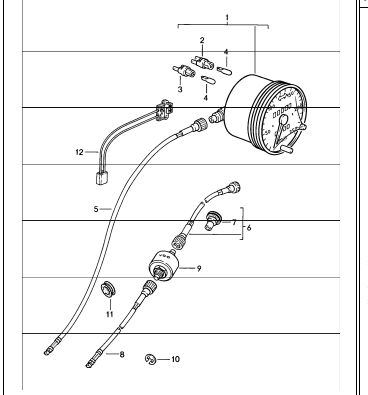

You are almost quite right, the magnet poles passing the aluminium cup that is behind the dial face induce an eddy current in the non-ferrous aluminium which makes the cup behave like an elctromagnet which is then attratcted to the poles of the magnet, FSD is resisted by a hair spring and the faster the rotation the more eddy current and more torque to turn the cup. All that is basic physiscs and some interesting lectures about this very thing were the subject of some Royal Institution Christmas Lectures many years ago, probably one of Professor Sir Eric Laithwaite's, and as I say your basic theory is unflawed, but the cable screws to the connection which is at about 30 degrees to the vertical face of the back of the speedo so there must be a pair of gears to take drive to the magnet. As the thrust face of the magnet spindle wears the clearance increases and this changing clearance is the reason for a wavering needle. There is another factor to the wavering; a poorly routed cable will cause a binding point and the cable will wind up fractionally then unwind as the cable overcomes the resistance giving inconsistant speed to the magnet. usually a slow waver is the magnet and a fast more like flickering is usually the cable, which may simply need lubricating