You should upgrade or use an alternative browser.

torque setting for wheel nuts

- Thread starter Alpine

- Start date

duncan_956

New member

I've read a few posts about torque settings and started me thinking - I've always gone down the road of putting my substantial weight behind it and doing them as tight as possible...

My car is a mark 4 golf gti, obviously a bit different from an S2, so what would the impact be on the car if not followed?

Diver944

Active member

If you undertighten them then once again they can work loose [

Either situation is not one I want to be in anytime soon [

duncan_956

New member

Thanks for the info, Paul.

Can't imagine that VW nuts would be made from the same soft alloy and they're not 20 years old, the thing that got me thinking was I've recently had all 4 tyres changed while in for a service at an independent garage. Occasionally while driving on the motorway the car will act as if it's windy (very, very slight movement) and I've put ithis down to either a different make of tyre from what I've been used to, gone from Goodyear to Dunlop, or a bit of tramlining. I don't feel this when driving down normal A/B roads.

......runs off to check wheel nuts...

How do you measure the torque settings? What type of tool would you use?

ORIGINAL: duncan_956

How do you measure the torque settings? What type of tool would you use?

You'll need to buy a good quality Torque Wrench.

Wigeon Incognito

New member

ORIGINAL: simonthomas

Just as well i didnt give it some beans when I left or I may have been overtaken by a round black rolling missile!

I've had that!

I was driving a flat bed truck through a zoo when it was closed so decided to see how fast I could go down the central path. I got up to about 50mph, went through a big dip on a curve in the path, heard a very loud clang, and saw my wheel overtaking me heading towards the gorilla lake!

Luckily I had no weight in the back so it stayed on three wheels.

Annoyingly I could blame nobody but myself - I'd changed the wheele earlier in the week but remembered I was called to an escape when I was putting the wheel back on so had only tightened the nuts finger tight.

Neil Haughey

New member

It's still something 99% of us do though . . . . . . . [8D]

Mike

Tam Lin

New member

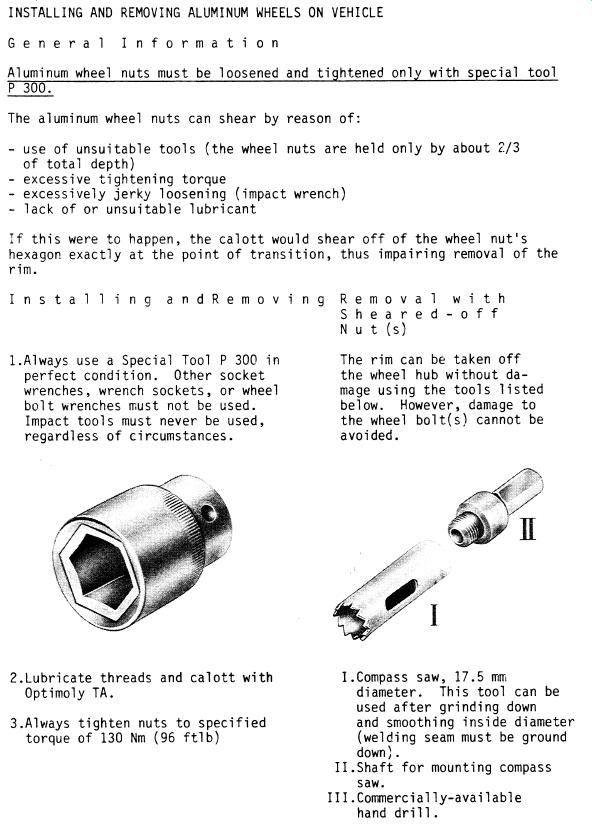

The Optimoly recommendation is in the Porsche workshop manual. In fact they consider it essential. I know Porsche don't always get it right, but given the almost unique light aluminium nut/MgAl wheel/steel bolt combination, I doubt many other people will have done as much testing as them on this particular fitment.

Hilux

New member

It's certainly important with a 944 because the wheel nuts are a very light, very soft alloy and if you overtighten them they can strip the thread and eventually come loose [] Let's not forget they are probably 20 years old if still original.

If they have lost their coating and are whitish in colour they should be changed.

I would have thought that he threads should always be totally clean for the torque readings to be correct. Lubrication can create a slip plane and change friction levels between surfaces however some bolts like con rod stretch or main bearing bolts require oiling if the manufacturer specs it

Also do NOT let a tyre centre (or yourself) use impact wrenches on alloy nuts, if you have then change them for they are brittle and the impact gun can create stress fractures.

a) If I torque the wheel nuts to 130Nm without a lubricant (with clean threads), the relative friction between the mating surfaces of the stud and the nut result in a torque of at or around 130Nm when the wrench 'clicks' at 130Nm.

b) If the threads on the studs are lubricated and then the nuts are torqued to 130Nm they are likely to travel very slightly further on the threads due to the lubricating properties of the Optimoly as there is less friction between the mating surfaces of the thread and nut. However, when the torque wrench 'clicks', the resulting torque setting is still at or around 130Nm.

Whichever way you look at it, I am still tightening the nuts to the same torque setting relative to the studs.

Only with option (b), the nuts will be less likely to seize onto the studs when I need to remove the wheels due to the anti-seize properties of the lubricant.

sawood12

New member

Another factor to consider here are that because you have alloy nuts on steel studs you will be getting an electrolytic cell set up as you do when dissimilar metals come into contact with eachother. This promotes corrosion and increases the liklihood of your nuts getting siezed on if you don't remove them regularly.

Posts made and opinions expressed are those of the individual forum members

Use of the Forum is subject to the Terms and Conditions

Disclaimer

The opinions expressed on this site are not necessarily those of the Club, who shall have no liability in respect of them or the accuracy of the content. The Club assumes no responsibility for any effects arising from errors or omissions.

Porsche Club Great Britain gives no warranties, guarantees or assurances and makes no representations or recommendations regarding any goods or services advertised on this site. It is the responsibility of visitors to satisfy themselves that goods and/or services supplied by any advertiser are bona fide and in no instance can the Porsche Club Great Britain be held responsible.

When responding to advertisements please ensure that you satisfy yourself of any applicable call charges on numbers not prefixed by usual "landline" STD Codes. Information can be obtained from the operator or the white pages. Before giving out ANY information regarding cars, or any other items for sale, please satisfy yourself that any potential purchaser is bona fide.

Directors of the Board of Porsche Club GB, Club Office Staff, Register Secretaries and Regional Organisers are often requested by Club members to provide information on matters connected with their cars and other matters referred to in the Club Rules. Such information, advice and assistance provided by such persons is given in good faith and is based on the personal experience and knowledge of the individual concerned.

Neither Porsche Club GB, nor any of the aforementioned, shall be under any liability in respect of any such information, advice or assistance given to members. Members are advised to consult qualified specialists for information, advice and assistance on matters connected with their cars at all times.