924Srr27l

New member

+ Fully modular

+ Fully upgradeable

+ Track use approved

+ Damping adjustable

+ Temp.-compensation

+ Choose; Comfort or Sport settings

+ Damping-upgrade better Stability & Cornering

+ More direct steering

+ Same or better comfort

+ Ride height adjustable

+ Springs replaceable

+ Rebuildable / Upgradeable

+ Option for camberplates

ARC (Anti Roll Control)®

After years of development Intrax developed a unique way to drastically reduce unwanted roll (lateral and longitudinal)

The car will have the comfort and all the other benefits of driving with "soft” springs like extra grip and traction,

until you take a corne or need to brake then ARC® will control ride height with the feel of a sport/race/rally setup.

While driving over a curb (Trackday), or through a pot hole the suspension will absorb them like driving with soft springs.

"Black Titan” coating

Which is applied on the guidance- and piston rod. Black Titan is an development from military aircraft industry.

Their engines must perform under the toughest conditions, they must function from +40°C up to -30°C.

After they fitted their engines with Black Titan, the service interval was increased by almost 100%.

The Black Titan coating cannot rust and is extremely hard and smooth, hence the piston friction is lowered

reducing oil temperatures, improving traction and extending life time under the severest conditions.

Intrax (Holland)

As you'd expect from an expensive (£4000 set) bespoke service & Product, they wanted to know many things about the car's use,

what mods have been done, the wheels & Tyres / brakes being used and also the car's current set up and handling

characteristics...etc

From this the final spec has now gone to build stage and I'm hoping delivery within 2-3 weeks.

We've agreed to use springs on the rear as well as keeping the 27mm Torsion bars, the coil springs will be located

with a low poundage helper spring which can be set uncompressed when the car's static weight is on the axle.

This means the car's spring rate will only use the Torsion spring initially and then under heavier loading / cornering the coil spring

will add to and make the total spring rate higher.

The Springs they make their own from lightweight carbon steel which are an unusual size

2.75" ID (70mm).

The fronts have 40 and the rear 50 positions of adjustment which is at a ratio of 70% Bump & 30% rebound.

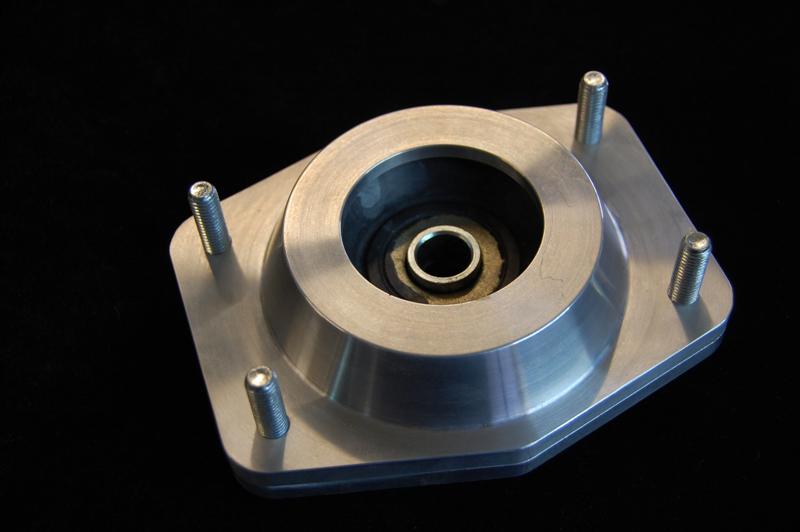

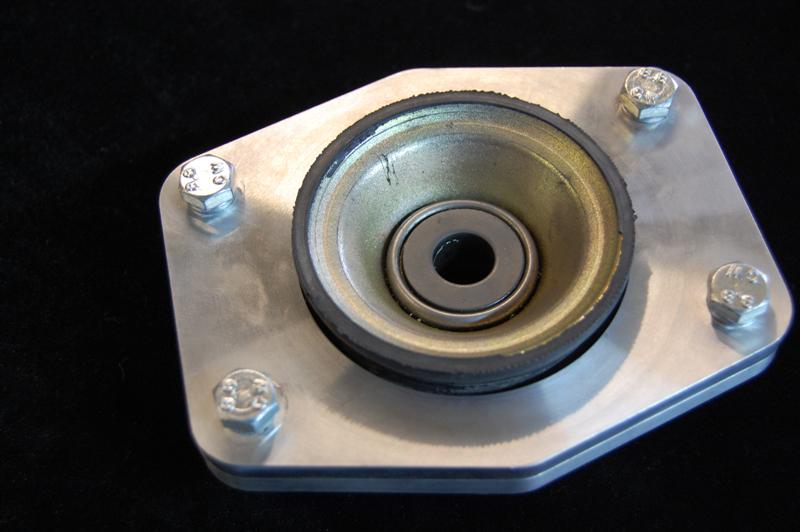

The special ARC valve only works in the bump motion, and I'm using standard rubber top mounts.

It is interesting for those that enjoy learning and understanding about things like handling, how it works,

and what it can do for you, but this is clearly not for everyone as some people see it too deep and complicated.

Normally the helper quashes to nothing at rest then any downward movement the main spring will be in force.

This is mostly used for coil springs only (like the front struts) but can also be used on the rear when an additional spring

(Coil) is fitted as a well as the (Torsion) Spring.

I wasn't keen on having any extra springs on the rear as the rear of the car feels very good,

(no wheelspin and no excessive bodyroll) hence I'm reluctant to introduce more stiffness, but the engineer

(Also a Racing driver & winner in Radical sportcars) convinced me that it's just as well that we spec a rear coil if I ever did

decide to attend another track day as it would be beneficial also because the dampers are adjustable with 50 clicks and the ARC

valve was designed / also works very well with hitting circuit kerbs (Btcc style)

So he suggested that I set the spring pan height to still show a relaxed Helper for an inch, then after the spring will

be assisting and adding it's resistance to the 220Lb Torsion bars.

They work in NM and the front springs are to be 34NM (190lbs) and the rear Coils 40NM (230Lbs) but because

of the different front & rear suspension designs and subsequently the MR (motion ratio), the wheel rates will be approx.

Front

Coil 190lbs , MR .90 (171 lbs)

Rear

Torsion bar 220Lbs MR .65 (143 Lbs)

Coil springs 230 lbs MR .65 (150 lbs)

So the rear Wheel Spring rate once the helper is coilbound and both springs are operational will be 293Lbs,

which is why I don't want this amount of stiffness at least not for the first inch or more , but only when really pushed.

It means the rear will have a dual rate, great for ride road quality and then the increase when cornering.

It may for once give the rear some oversteer balance, which if it does and it's too much the springs can be changed

and decreased, but for now I'm going with their spec & expertise.

I've got plenty of wheels and Tyres (Widths & Sizes) to be doing more trials once they are installed, but I'm not planning on

fitting them until the modified wishbones and stub axles are also done and ready to fit...

The idea to test for the first time a revised corrected wishbone Geometry, with less bumpsteer and also

all 4 corners being controlled by the trick valving is far more appealing and effective to judge the change all in one go.

There will also be less unsprung weight (aluminium strut bodies).

Intrax have a vast amount of experience in what they do, but I also need and like to understand what it is they are doing so for sure I have asked the question about will I have an abrupt rear end with effectively 2 pairs of springs but their answer is no, because what their valving and the trick ARC valve is doing is replicating an electronic system which many car's have these days. Which gives a good ride quality but stiffens when cornering hard.

The ARC valve makes the bump stroke much harder than normal sport shocks, because when it encounters a fast piston movement (Bump, pot hole, Curb etc..) it relaxes within mili-seconds and softens.

Of it didn't the compliance would be rock hard and the ride quality and crashy feeling some may of experienced when you've run hard shocks on the road?

When the shock absorber is loaded slowly EG when tipping into a corner with a slower not abrupt amount of force the valving and ARC valve has a lot of strength & support and holds and controls the car's body very well. It's almost like having 2 spring rates in that the shock varies the resistance it offers dependent on how slow or fast the piston rod travels from the road surfaces.

So getting back to these rear coils, which with the intended set up will only come in to play when a very high

amount of cornering load is applied to them which at this point is a good thing as it means the harder I push the more support I will get.

It could offer some oversteer which usually as you know the harder you push a 944 it understeers...

So this could "trim" the rear quite nicely mid to corner exit and reduce the understeer.

Once I'm happy with the set up I might return to Oulton park just to see how they react.

Here's a example from an American Racer... On a 930 who had Torsion bars front & Rear but also fitted additional rear coil springs:

-------------------------------------------------------------------------------------------------------------------------------------

I prepared a 2720 lb track 930 with 23/31 T bars and 250 lb helper coils in the rear (along with a number of other suspension mods as well). The car ran on the track with 520 hp, on 275 and 315 Nitto NT-01 tires. My goal was increase the rear spring rate but I wanted to avoid full coilovers in order to alleviate the need for reinforcement of the rear shock towers. I felt that the relatively minimal coil spring rate of 250 lb/in did not impose enough load to the shock towers to create a problem. I wanted to reduce the squat on acceleration that was causing odd and undesirable handling during corner exits. It also made for a platform that allowed finer, easier adjustment for ride height and corner balancing.

The car handled perfectly -- it felt very linear and predictable. There was no tendency for excessive oversteer, and certainly no "snap oversteer" as has been suggested. It felt stable in slower corners (entry speeds of 35 mph) as well as the highest speed sweepers, at over 145 mph. There was no problem with setup, no strange noises coming from the suspension, and no issues with the two different springs "fighting each other." In all, it seemed like an ideal setup that accomplished the goals that I was looking for. BTW, I got the coilovers and some revalved shocks from Rebel racing and was happy with the transaction.

There are several seriously fast track 930s around here that are running rear coils and torsion bars with great success. I'm one who's not afraid of an engineering analysis or theoretical discussion, but sometimes, the best way to assess a particular setup is to also consider empirical data -- such as lap times -- from drivers who have demonstrated success.

I would certainly think that to run such a setup on the street would be absolutely fine.

-------------------------------------------------------------------------------------------------------------------------------------

Bespoke stub axles & wishbones are also being built to eradicate bumpsteer

The plan is fit all these items at once for a very dramatic effect / improvement on public roads.

R

www.924srr27l.co.uk