Rocky997

New member

Can anyone clarify something for me please.

I am just in the process of removing my wheels and giving the the hubs a rub down and clean before sealing the wheels and calipers.

I have also cleaned up the slightly tarnished wheel bolts.

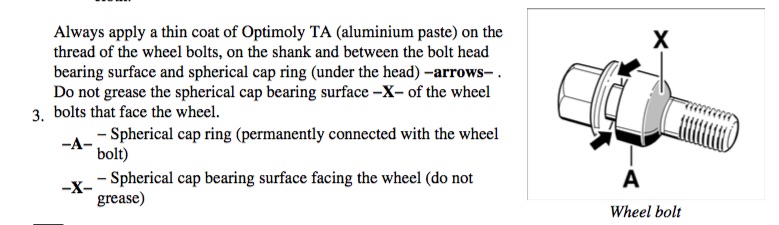

I have found two different torque settings in the porsche imanuals. 2009-2011; so I am assuming correct for me (997.2) says 130nm and to grease the threads with aluminium paste...so wet torque settings. Later manual says 160nm and dry. I am just checking as I was always told although it would seem common sense that greasing wheel bolts is a no no.

Any advice please folks.

Thanks in advance.

I am just in the process of removing my wheels and giving the the hubs a rub down and clean before sealing the wheels and calipers.

I have also cleaned up the slightly tarnished wheel bolts.

I have found two different torque settings in the porsche imanuals. 2009-2011; so I am assuming correct for me (997.2) says 130nm and to grease the threads with aluminium paste...so wet torque settings. Later manual says 160nm and dry. I am just checking as I was always told although it would seem common sense that greasing wheel bolts is a no no.

Any advice please folks.

Thanks in advance.