SidewaysSteve

New member

Recently I bought a little Boxster 2.7, cracking clean car with full Porsche and Indy Service history on a 2000 W Plate with 122,000 miles on her.

Car looked to be the perfect Porsche, with its history, loads of receipts for parts, tyres etc etc and more importantly a new clutch and flywheel fitted back in July and with only 3,000 miles on her up until now.

On the test drive she was fine, no nasty noises, smoke, etc etc however what I didnt do (despite having bnought plenty of cars and repaired even more) was give it a proper hard drive on th etest i.e. take it right up the revs fully.

I reved her out fairly well but changed around 5000 rpm as it seemed smooth enough and was pulling well.

Drove home the 420 miles back to Scotland and in the morning went out and gave my new toy a good clean and polish, however there were some oil spots on my driveway....

To cut a long story short the recently fitted dual mass flywheel had failed and at revs above 5,500 rpm was causing some severe engine vibration which in turn was causing the RMS to leak and was making the clutch cover contact the gearbox housing and had scraped the metal inside it.

Over the weekend just past I stripped down the back of the car, cleaned up all the mess and fitted a nice new LUK dual mass flywheel and a new RMS.

Once refitted and back on all 4 wheels I took her for a spin, once again above 5,500 rpm I had heavy vibrations so clearly something was still imbalanced.

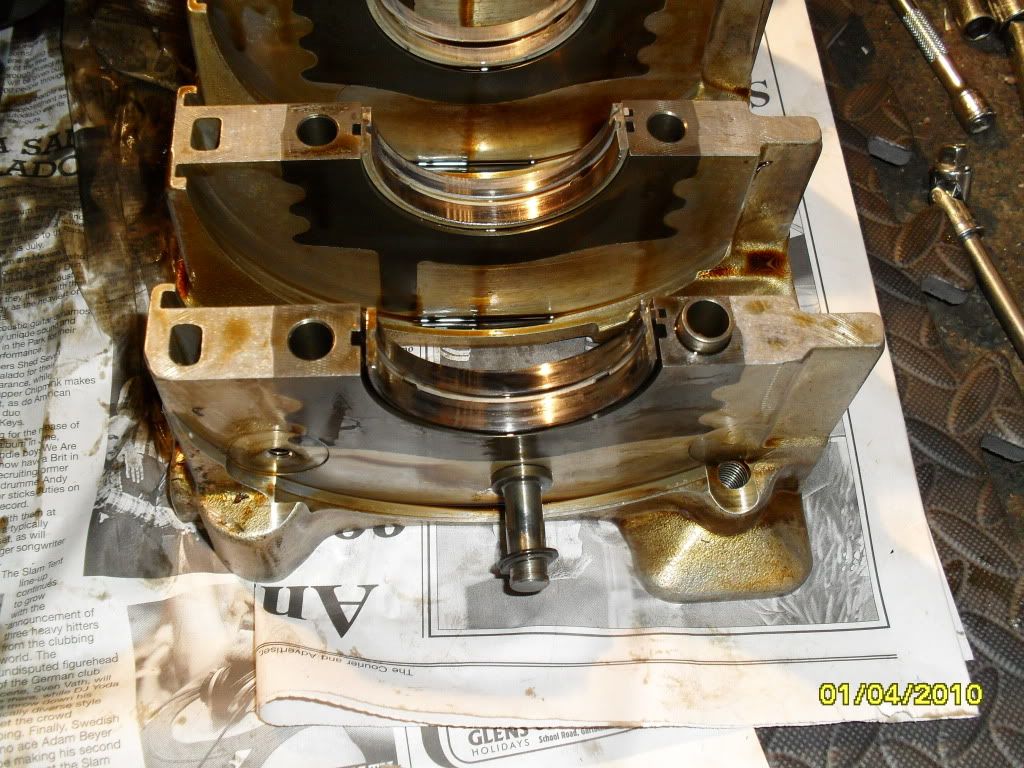

I stripped the box back off again and cranked the engine by had with the clutch removed and only the flywheel fitted to discover it was wobbling like a wheel with a buckle and therefore causing the vibrations at certain rpm's.

How was this possible ??? brand new flywheel and its wobbling about !!

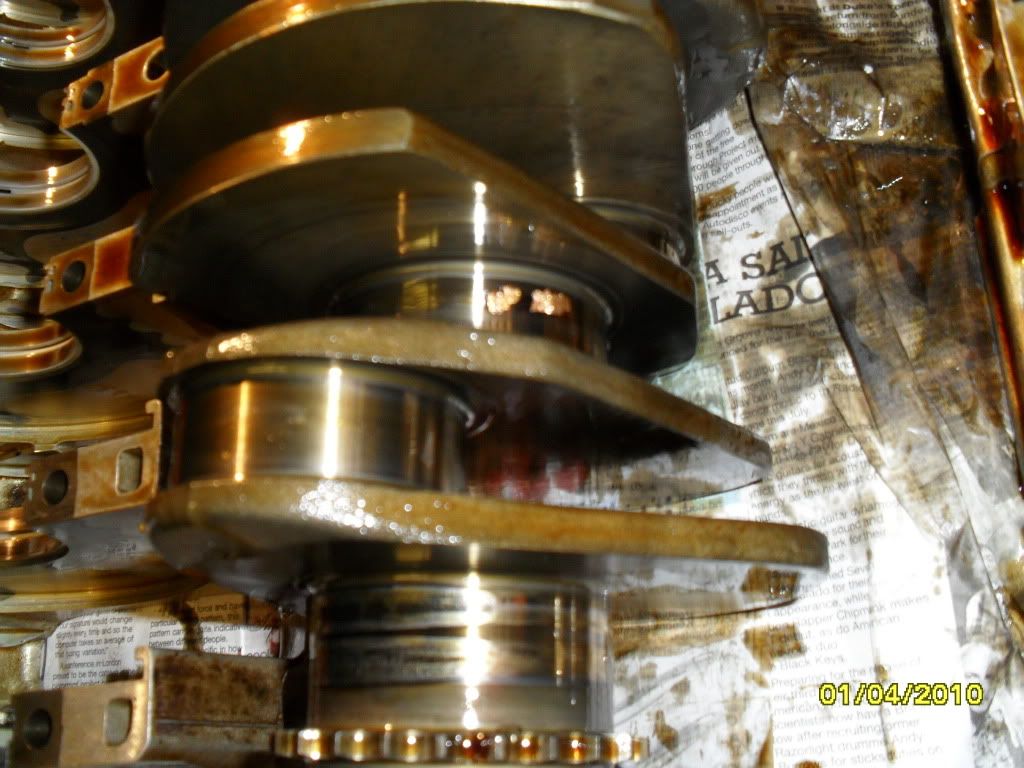

Well, its possible because with the flywheel removed and by rotating the crank you can clearly see the flywheel end of the crank "orbiting" within the RMS which I may add was now damaged again due to the movement of the crank.

I have not had a chance to investigate further yet HOWEVER it would appear that the crankshaft itself has somehow managed to warp or bend at the flywheel end.

Piecing together data I have via receipts and from speaking to M96 engine failure specialists, at this point we have come to the following conclusion.

The clutch/flywheel fitted in July were done as we think the car had suffered a DMF/Clutch failure. We think that the failure of the original DMF has caused such an imbalance that it has warped or possibly fractured the crankshaft.

The new DMF was then fitted in July and the car was indeed running however at high rpm the distorted crank was causing the whole rotating assembly to be out of balance which in turn was worsening the situation and eventually caused the NEW DMF to fail too.

When the July DMF failed it added to the already imbalanced vibrations which has distroted/cracked the crankshaft even more.

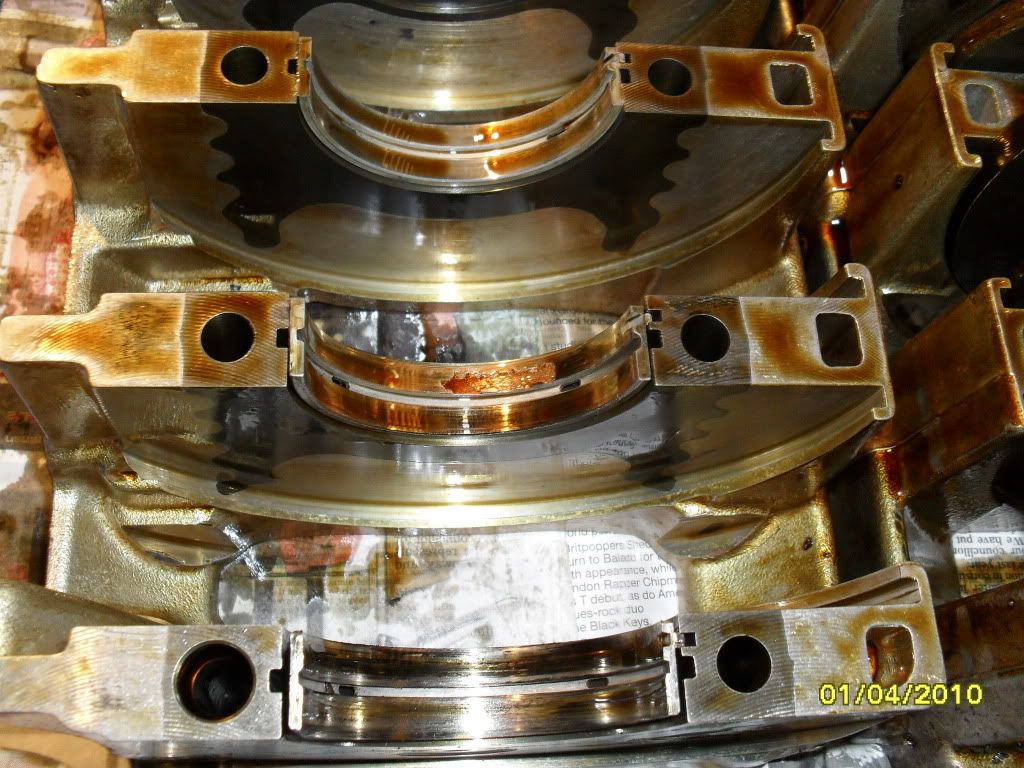

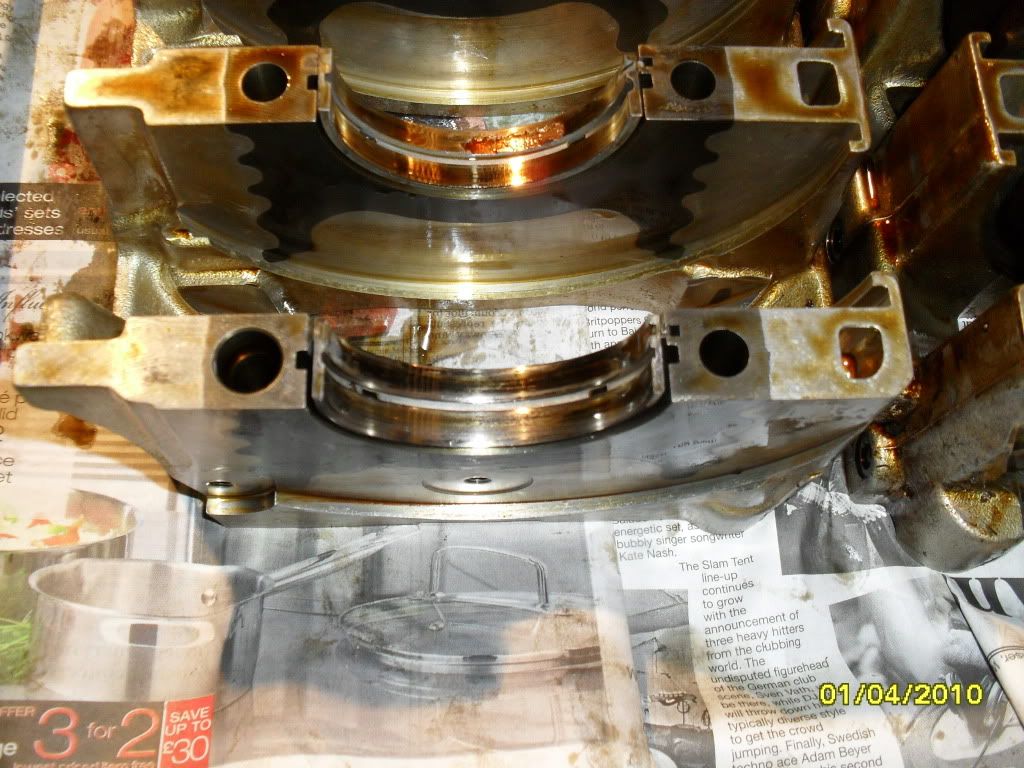

The end result here is that the engine will need to be pulled and stripped to determine what parts are damaged and what parts are salvagable.

Hopefully due to catching this issue early on I may be lucky and manage to rebuild the engine using a new crank and bearings.

The moral of this story is that when you replace the clutch on one of these engines I would STRONGLY suggest paying the extra £400 ish quid for a NEW dual mass flywheel, as if one fails you could be looking at seriious bills for repair.

I am in the lucky position that I can do all this work myself, therefore cost to me is only that of parts. If a dealership or any other garage would have taken on the work I have done you would easily be into thousands of pounds for labour.

I will be pulling the engine fully and stripping it on Saturday so I will take pictures and keep you all informed of the findings.

For now though, im so glad I decided to buy a Porsche ....... LOL

Car looked to be the perfect Porsche, with its history, loads of receipts for parts, tyres etc etc and more importantly a new clutch and flywheel fitted back in July and with only 3,000 miles on her up until now.

On the test drive she was fine, no nasty noises, smoke, etc etc however what I didnt do (despite having bnought plenty of cars and repaired even more) was give it a proper hard drive on th etest i.e. take it right up the revs fully.

I reved her out fairly well but changed around 5000 rpm as it seemed smooth enough and was pulling well.

Drove home the 420 miles back to Scotland and in the morning went out and gave my new toy a good clean and polish, however there were some oil spots on my driveway....

To cut a long story short the recently fitted dual mass flywheel had failed and at revs above 5,500 rpm was causing some severe engine vibration which in turn was causing the RMS to leak and was making the clutch cover contact the gearbox housing and had scraped the metal inside it.

Over the weekend just past I stripped down the back of the car, cleaned up all the mess and fitted a nice new LUK dual mass flywheel and a new RMS.

Once refitted and back on all 4 wheels I took her for a spin, once again above 5,500 rpm I had heavy vibrations so clearly something was still imbalanced.

I stripped the box back off again and cranked the engine by had with the clutch removed and only the flywheel fitted to discover it was wobbling like a wheel with a buckle and therefore causing the vibrations at certain rpm's.

How was this possible ??? brand new flywheel and its wobbling about !!

Well, its possible because with the flywheel removed and by rotating the crank you can clearly see the flywheel end of the crank "orbiting" within the RMS which I may add was now damaged again due to the movement of the crank.

I have not had a chance to investigate further yet HOWEVER it would appear that the crankshaft itself has somehow managed to warp or bend at the flywheel end.

Piecing together data I have via receipts and from speaking to M96 engine failure specialists, at this point we have come to the following conclusion.

The clutch/flywheel fitted in July were done as we think the car had suffered a DMF/Clutch failure. We think that the failure of the original DMF has caused such an imbalance that it has warped or possibly fractured the crankshaft.

The new DMF was then fitted in July and the car was indeed running however at high rpm the distorted crank was causing the whole rotating assembly to be out of balance which in turn was worsening the situation and eventually caused the NEW DMF to fail too.

When the July DMF failed it added to the already imbalanced vibrations which has distroted/cracked the crankshaft even more.

The end result here is that the engine will need to be pulled and stripped to determine what parts are damaged and what parts are salvagable.

Hopefully due to catching this issue early on I may be lucky and manage to rebuild the engine using a new crank and bearings.

The moral of this story is that when you replace the clutch on one of these engines I would STRONGLY suggest paying the extra £400 ish quid for a NEW dual mass flywheel, as if one fails you could be looking at seriious bills for repair.

I am in the lucky position that I can do all this work myself, therefore cost to me is only that of parts. If a dealership or any other garage would have taken on the work I have done you would easily be into thousands of pounds for labour.

I will be pulling the engine fully and stripping it on Saturday so I will take pictures and keep you all informed of the findings.

For now though, im so glad I decided to buy a Porsche ....... LOL