AVI_8

New member

C2 dweller, yes slightly more complex than my first car also, a 3 litre Capri in 1987! Did my own valve adjustment on that one also.

A tip that I forgot to mention, after youve removed the nuts from the valve covers, under them will be washers, it's quite difficult to get your fingers into some of them due to location, I used a pair of angled long nosed pliers to remove the washers.

Now to the valve adjustment, tip here it's fiddly until you've got the technique sorted, which will happen after a couple of valves, if it's not working for you straight away, leave it for a few mins, swear a bit!, go and make a coffee and come back to it.

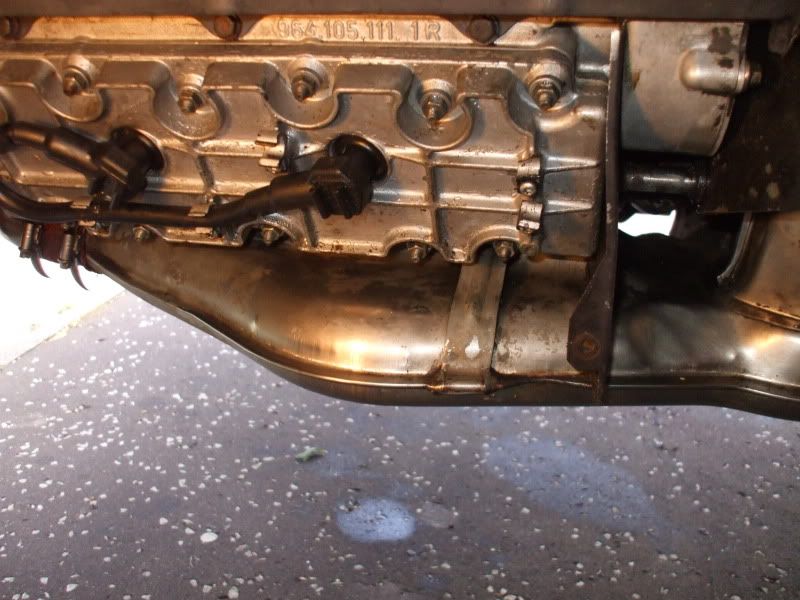

Firstly, you need to rotate the engine using a 24 mil tool, again your service kit in the vehicle will have one of them in the tool kit. Use that to turn the engine with the fan nut (clockwise) it'll be easy to turn as you've removed one set of plugs per cylinder (you've taken the car out of gear??) turn the engine until the Z1 mark on the crankshaft pulley is at zero degrees (12 o'clock) it will align with the Top dead centre mark on the housing behind the pulley. Pic attached though it's out of focus unfortunatelly.

Have a look yourself it'll be obvious.

Now the crankshaft will rotate twice per firing order cycle....The firing order is 1-6-2-4-3-5, To go to basics for those of you who don't know, the rear left cylinder is No.1, the middle left is 2, the front left is 3, right rear is 4, right middle,5, right front 6.

One revolution of the crank will fire cylinder 1-6-2, the next revolution will fire 4-3-5

Hope I'm not confusing you here it quite simple!

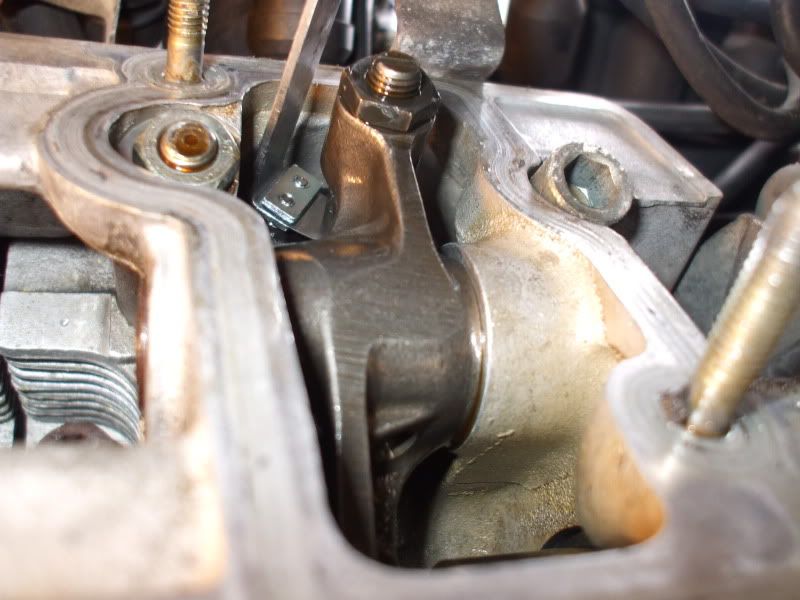

You want to start adjusting the valves on cylinder 1, so turn the crank until you have Z1 alligned, this will either be Top dead centre for cylinder 1 or cylinder 4, how you tell is by checking the valve rockers, go to cylinder one, try to move the rockers from side to side, if they're (both) loose, (upper and lower rockers rear left of engine) , it'll be quite noticeable, then you've got cylinder 1 on TDC, if they're not then check cylinder 4 (rear right) if they're loose then you need to turn the engine through one full turn.

Ok now you've got TDC for no.1 you can start to adjust the valves using this tool

You'll need it, a normal set of feeler guages wont work with the 911, I got one from my OPC for around £30, including 5 blades (I didn't break any doing mine)

![. [FONT=verdana,geneva"] [FONT=verdana,geneva"]](/forum/styles/default/pcgb/space.gif) Nice write up, enjoyed the read and pics (most essential). So, what's your next task? Get that in here too ;-)

Nice write up, enjoyed the read and pics (most essential). So, what's your next task? Get that in here too ;-)