Chaps,

The brakes on my S2 were distinctly lacklustre recently so I took the wheels off to have a look and discovered that the front calipers were afflicted by the dreaded 'plate lift'. I know it is possible to get calipers professionally refurbished but being short on money at the moment (but having plenty of time) I tackled it myself and took some photos. I did the same to the rear calipers about 4 or 5 years ago, soon after I bought the car, and this time it was the turn of the fronts.

I was surprised by how little lift was necessary to jam the pads up. One of the pads wouldn't slide out at all (and hence wouldn't have been able to exert any force onto the disk), and let when I looked at the caliper I was dubious as to whether there was any lift at all. Moral of the story is that these things don't have much tolerance in them.

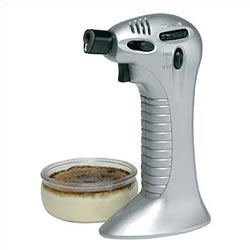

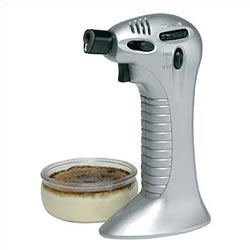

The calipers come off readily; two 19mm bolts holding them on, and a 14mm spanner to get the brake hose off. The bolts holding the plates in put up a fair fight, but not too bad - there was the usual loctite on the threads and they were pretty tight, But the heads weren't too rusty so there was moderate purchase available on them. The solution is heat; I used a small (kitchen) butane blowtorch with a fine pencil flame to toast the heads of the bolts and destroy the loctite - like this one, but there are hundreds available:

The small flame allows you to locally heat just the head of the bolt - you need to avoid toasting the piston seals which are very close by. I cleaned the bolts carefully (allows better heat transfer to them) and then heated them good and hard - four or five minutes with a good flame, until they started making a faint crackling noise. Some didn't respond to this, so I cut a notch in the top of them and used a hammer and cold chisel to hit them 'round until they were free. (This is quite a lot more brutal tho' and best avoided if you can.)

Once the bolts are out then I removed the plates (carefully, to avoid damaging the seals) and cleaned the corrosion away from behind them with a wire brush. (If you aren't in a rush you can have them shot-blasted and replace the seals, but I needed to use the car and didn't have the time for this.) Once all the corrosion is out you can apply lotions and unguents to slow further corrosion in the future. I used some good 'ol smoothrite paint; it's suitable for moderate temperatures, and calipers never get as hot as people think they do (if they did then the rubber seals in them would be destroyed!) While I was at it, I cleaned the rest of the caliper as well and painted the front and top.

Drying smoothrite can be helped with a little heat:

(I dearly hope my wife never looks at this forum ... ) The plates are re-usable if they aren't too bent, but do benefit from some cleaning as well - in my case, with a wire brush on the end of an electric drill. Here are some cleaned and un-cleaned ones.

You need to refit new bolts; they are standard M6's, and I used normal-head stainless ones. This will mean that next time the calipers are dismantled it will be MUCH easier to get the bolts out.

You do need to file the heads a little to get clearance for the pads, but this is a trivial job and the ease of future removal makes it well worthwhile. Here is a picture showing the slightly filed heads of the bolts. Use a ruler (or other straight edge) to ensure that they sit slightly behind the plane of the plates.

This picture also shows the copper grease used when re-assembling; I put a LOT of it behind the plates, in an attempt to keep future corrosion at bay.

Once the calipers were re-built it was trivial to put them back on the car and bleed the brakes. An easy-bleed kit is worth it's weight in gold here - making a 90-minute long two-person job into a 20-minute long one person job. Well worth £15 at your local motor factors.

And the end result? Brakes that work as they should; firm pedal feel and lots of bite (pushing well into the ABS from 50mph on a warm dry road.) And shiny black calipers!

Oli.

The brakes on my S2 were distinctly lacklustre recently so I took the wheels off to have a look and discovered that the front calipers were afflicted by the dreaded 'plate lift'. I know it is possible to get calipers professionally refurbished but being short on money at the moment (but having plenty of time) I tackled it myself and took some photos. I did the same to the rear calipers about 4 or 5 years ago, soon after I bought the car, and this time it was the turn of the fronts.

I was surprised by how little lift was necessary to jam the pads up. One of the pads wouldn't slide out at all (and hence wouldn't have been able to exert any force onto the disk), and let when I looked at the caliper I was dubious as to whether there was any lift at all. Moral of the story is that these things don't have much tolerance in them.

The calipers come off readily; two 19mm bolts holding them on, and a 14mm spanner to get the brake hose off. The bolts holding the plates in put up a fair fight, but not too bad - there was the usual loctite on the threads and they were pretty tight, But the heads weren't too rusty so there was moderate purchase available on them. The solution is heat; I used a small (kitchen) butane blowtorch with a fine pencil flame to toast the heads of the bolts and destroy the loctite - like this one, but there are hundreds available:

The small flame allows you to locally heat just the head of the bolt - you need to avoid toasting the piston seals which are very close by. I cleaned the bolts carefully (allows better heat transfer to them) and then heated them good and hard - four or five minutes with a good flame, until they started making a faint crackling noise. Some didn't respond to this, so I cut a notch in the top of them and used a hammer and cold chisel to hit them 'round until they were free. (This is quite a lot more brutal tho' and best avoided if you can.)

Once the bolts are out then I removed the plates (carefully, to avoid damaging the seals) and cleaned the corrosion away from behind them with a wire brush. (If you aren't in a rush you can have them shot-blasted and replace the seals, but I needed to use the car and didn't have the time for this.) Once all the corrosion is out you can apply lotions and unguents to slow further corrosion in the future. I used some good 'ol smoothrite paint; it's suitable for moderate temperatures, and calipers never get as hot as people think they do (if they did then the rubber seals in them would be destroyed!) While I was at it, I cleaned the rest of the caliper as well and painted the front and top.

Drying smoothrite can be helped with a little heat:

(I dearly hope my wife never looks at this forum ... ) The plates are re-usable if they aren't too bent, but do benefit from some cleaning as well - in my case, with a wire brush on the end of an electric drill. Here are some cleaned and un-cleaned ones.

You need to refit new bolts; they are standard M6's, and I used normal-head stainless ones. This will mean that next time the calipers are dismantled it will be MUCH easier to get the bolts out.

You do need to file the heads a little to get clearance for the pads, but this is a trivial job and the ease of future removal makes it well worthwhile. Here is a picture showing the slightly filed heads of the bolts. Use a ruler (or other straight edge) to ensure that they sit slightly behind the plane of the plates.

This picture also shows the copper grease used when re-assembling; I put a LOT of it behind the plates, in an attempt to keep future corrosion at bay.

Once the calipers were re-built it was trivial to put them back on the car and bleed the brakes. An easy-bleed kit is worth it's weight in gold here - making a 90-minute long two-person job into a 20-minute long one person job. Well worth £15 at your local motor factors.

And the end result? Brakes that work as they should; firm pedal feel and lots of bite (pushing well into the ABS from 50mph on a warm dry road.) And shiny black calipers!

Oli.