You should upgrade or use an alternative browser.

DIY Caliper Refurbishment

- Thread starter zcacogp

- Start date

EddySpaghetti

New member

Just a word of caution to others looking to do this - my caliper retaining bolts were seized extremely fast. If yours are similar then you may have to resort to taking the hubs off the lower wishbones and the struts to get the calipers off (via a mechanics workshop to get the bolts drilled out). If your caliper bolts are that tight its entirely likely that all the others to get the hubs off will be well a bitch to remove too, so what I thought would be a 'couple of weekends' job ended up taking four (and car was obviously unusable throughout) - so just beware and check that those caliper bolts will come out before committing to the full job if you lack time. - I only just got finished in time for holiday I had booked to go to the 'ring last summer, hence the slightly rushed job on the re-paint, which was a shame after a lot of effort.

I will probably strip and re-do later this summer once the other work on my car is done, in prep. for another European summer tour. I can't wait

robwright

New member

ORIGINAL: DavidL

Its always amazed me that the weld itself is strong enough to withstand the pressure necessary to drive the nuts out. I mean if they are that stuck you need real leverage to shift them won't the weld break?

Presumably not but it still surprises me.

The allen key doesn't afford you much leverage at all especially if the heads are corroded. Once you get a decent enough weld on the head of the screw, being careful not to weld to the caliper plate as well [&:] it is quite easy to crack them with a small spanner.

robwright

New member

ORIGINAL: EddySpaghetti

This is a great post, thanks guys. I wish I had done a better job of repainting my calipers after the rebuild, but I was in a rush at the time and used inadequate spray paint - I don't think I realised I could have got such a decent finish using paint in a tin and a brush (that's what you did right?)

The first caliper I brushed the base coat on hoping it would give a deaper finish before spraying them. The other three I just sprayed at least three coats on them. Got the same result but with a smoother finish. If you have the proper spray equipment it's a lot better than using rattle cans.

DavidL - I had similar thoughts to you about the strength of the weld when trying to get badly corroded screws out. Rob, thanks for answering the question.

Oli.

TTM

Well-known member

ORIGINAL: zcacogp fronts.

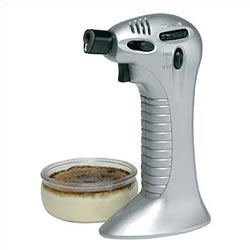

I used a small (kitchen) butane blowtorch with a fine pencil flame to toast the heads of the bolts and destroy the loctite - like this one, but there are hundreds available:

The small flame allows you to locally heat just the head of the bolt - you need to avoid toasting the piston seals which are very close by. I cleaned the bolts carefully (allows better heat transfer to them) and then heated them good and hard - four or five minutes with a good flame, until they started making a faint crackling noise. Some didn't respond to this, so I cut a notch in the top of them and used a hammer and cold chisel to hit them 'round until they were free. (This is quite a lot more brutal tho' and best avoided if you can.)

I just spent half an hour heating ONE bolt with a domestic blowtorch - epic fail [>:]

At this point the brutal method sounded tempting but the metal is so soft that the head will self destroy if I keep hitting it.

Diver944

Active member

ORIGINAL: zcacogp

Not everyone has a MIG set though Olli.

I bet Olli's Creme Brulee's are a lot crisper than ours

Regards,

Clive.

Posts made and opinions expressed are those of the individual forum members

Use of the Forum is subject to the Terms and Conditions

Disclaimer

The opinions expressed on this site are not necessarily those of the Club, who shall have no liability in respect of them or the accuracy of the content. The Club assumes no responsibility for any effects arising from errors or omissions.

Porsche Club Great Britain gives no warranties, guarantees or assurances and makes no representations or recommendations regarding any goods or services advertised on this site. It is the responsibility of visitors to satisfy themselves that goods and/or services supplied by any advertiser are bona fide and in no instance can the Porsche Club Great Britain be held responsible.

When responding to advertisements please ensure that you satisfy yourself of any applicable call charges on numbers not prefixed by usual "landline" STD Codes. Information can be obtained from the operator or the white pages. Before giving out ANY information regarding cars, or any other items for sale, please satisfy yourself that any potential purchaser is bona fide.

Directors of the Board of Porsche Club GB, Club Office Staff, Register Secretaries and Regional Organisers are often requested by Club members to provide information on matters connected with their cars and other matters referred to in the Club Rules. Such information, advice and assistance provided by such persons is given in good faith and is based on the personal experience and knowledge of the individual concerned.

Neither Porsche Club GB, nor any of the aforementioned, shall be under any liability in respect of any such information, advice or assistance given to members. Members are advised to consult qualified specialists for information, advice and assistance on matters connected with their cars at all times.