Oli, basically the splitter shape was copied from another splitter which is ment for 951, not so demanding after all. After that i have changed shape a bit, to get it fit better. Splitter in the picture is not ready yet, it lacks mounting holes and some other cuttings which were made after i took the picture. Most of fiberglass jobs are more or less copying another peoples work or copies from oem metal parts. Most of us are able to do glassfibre parts after practising.

Making parts from oem metal parts are really easy; here's 911 bumpers i have made

Rear bumber mold (does not look fancy..)

Almost ready GTS style headlamp bucket molds

When finished, product will look like this

I am going to take a mold off this rare '80's Brixner apron for a friend

That red 944 is wrecked, only apron is left, i bought it for 30€

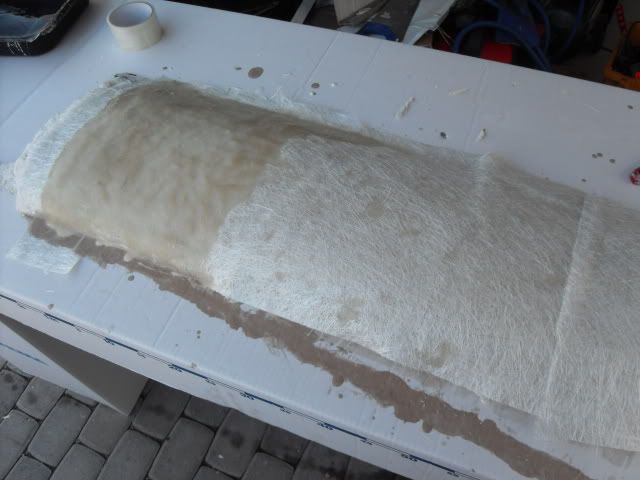

We made several splitter for the whole "gang" about 5 years ago. Here's few pictures of that session

Making a vented batch panel

I am currently making a big rear wing for a friends S2 race car. Wing's shape is copied from a wrecked wing of GT3 CUP car.Wing to be copied is damaged quite badly, can take just about 70cm long molds of it. After that put several mold together to get about 170cm long final mold.

Damaged wing

Making mold