Chaps,

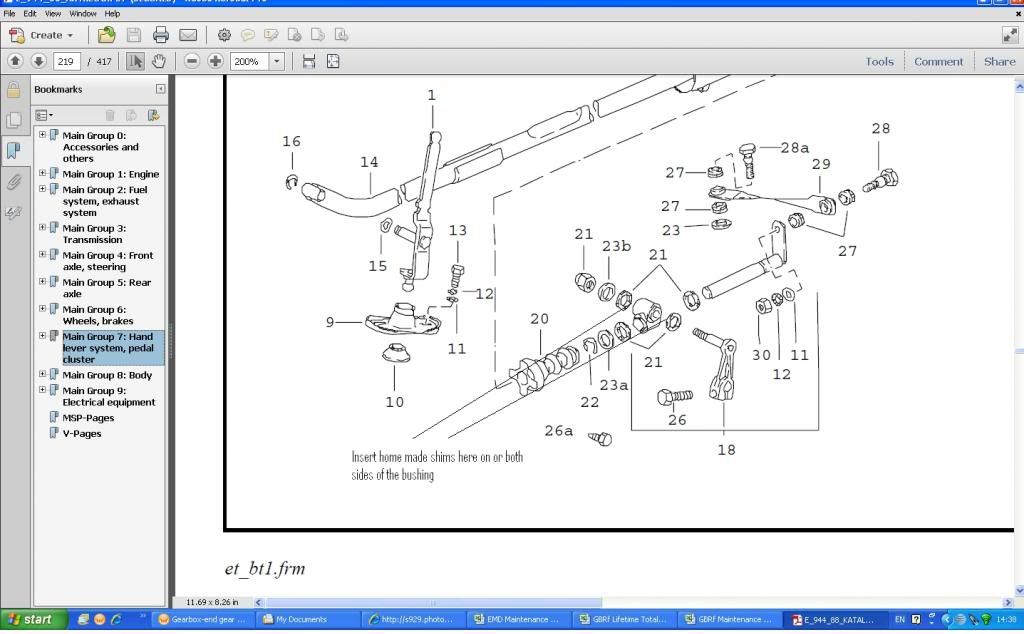

Quickie. I am planning to improve on the rather old and worn gearshift mechanism on top of the gearbox on my S2. I know what I plan to do, but in order to do this I will need to gain access to the top of the 'box to remove the old mechanism and both make and fit the new mechanism.

How low can you get the gearbox without taking it off the torque tube? I have had it off before (to do the clutch) but that was 4 years ago and I can't remember what sort of access you get with it still attached. I am guessing the easiest way to lower it is to un-bolt the bolts at the ends of the crossmember? (When I did the clutch I undid the gearbox mount from the crossmember which was a real fiddle.) How restrictive is everything else? For instance, do I have to remove the exhaust and driveshafts to get to maximum drop?

I have had a fiddle around without removing anything and, while I can just about get my hands onto the mechanism I can't see anything, and don't have enough space to get any tools in. It will have to come down 6-9 inches to do what I want to do.

Oli.

Quickie. I am planning to improve on the rather old and worn gearshift mechanism on top of the gearbox on my S2. I know what I plan to do, but in order to do this I will need to gain access to the top of the 'box to remove the old mechanism and both make and fit the new mechanism.

How low can you get the gearbox without taking it off the torque tube? I have had it off before (to do the clutch) but that was 4 years ago and I can't remember what sort of access you get with it still attached. I am guessing the easiest way to lower it is to un-bolt the bolts at the ends of the crossmember? (When I did the clutch I undid the gearbox mount from the crossmember which was a real fiddle.) How restrictive is everything else? For instance, do I have to remove the exhaust and driveshafts to get to maximum drop?

I have had a fiddle around without removing anything and, while I can just about get my hands onto the mechanism I can't see anything, and don't have enough space to get any tools in. It will have to come down 6-9 inches to do what I want to do.

Oli.