oilman

New member

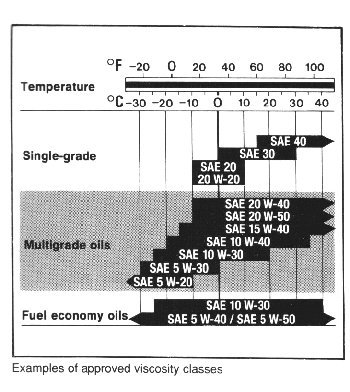

The problem with 5w-50 is the "wide viscosity" range it covers which makes it almost impossible to make it "shear stable".

You see to meet 5w and sae 50, it needs bucket loads of VI Improver in it to prop it up which makes it prone to shearing at high temperatures that's why 5w-40 and 10w-50 are better options.

As I have mentioned before, the oil would be an sae 50 on day one but would shear back with use (a couple of thousand miles) to an sae 40 or 30.

A shear stable 40 would give better long term protection.

Here is the science:

VI improvers are polymers that expand and contract with changes in temperature. At low temperatures they are very compact and affect the viscosity of a lubricant very little. But, at high temperatures these polymers "expand" into much larger long-chain polymers which significantly increase the viscosity of their host lubricant.

So, as the basestock loses viscosity with increases in temperature, VI improvers "fight back" against the viscosity drop by increasing their size. The higher the molecular weight of the polymers used, the better the power of "thickening" within the lubricant. Unfortunately, an increase in molecular weight also leads to an inherent instability of the polymers themselves. They become much more prone to shearing within an engine.

As these polymers are sheared back to lower molecular weight molecules, their effectiveness as a VI improver decreases. Unfortunately, because petroleum basestocks are so prone to viscosity loss at high temperatures, high molecular weight polymers must be used. Since these polymers are more prone to shearing than lower molecular weight polymers, petroleum oils tend to shear back very quickly. In other words, they lose their ability to maintain their viscosity at high temperatures

Cheers

Simon

You see to meet 5w and sae 50, it needs bucket loads of VI Improver in it to prop it up which makes it prone to shearing at high temperatures that's why 5w-40 and 10w-50 are better options.

As I have mentioned before, the oil would be an sae 50 on day one but would shear back with use (a couple of thousand miles) to an sae 40 or 30.

A shear stable 40 would give better long term protection.

Here is the science:

VI improvers are polymers that expand and contract with changes in temperature. At low temperatures they are very compact and affect the viscosity of a lubricant very little. But, at high temperatures these polymers "expand" into much larger long-chain polymers which significantly increase the viscosity of their host lubricant.

So, as the basestock loses viscosity with increases in temperature, VI improvers "fight back" against the viscosity drop by increasing their size. The higher the molecular weight of the polymers used, the better the power of "thickening" within the lubricant. Unfortunately, an increase in molecular weight also leads to an inherent instability of the polymers themselves. They become much more prone to shearing within an engine.

As these polymers are sheared back to lower molecular weight molecules, their effectiveness as a VI improver decreases. Unfortunately, because petroleum basestocks are so prone to viscosity loss at high temperatures, high molecular weight polymers must be used. Since these polymers are more prone to shearing than lower molecular weight polymers, petroleum oils tend to shear back very quickly. In other words, they lose their ability to maintain their viscosity at high temperatures

Cheers

Simon