robwright

New member

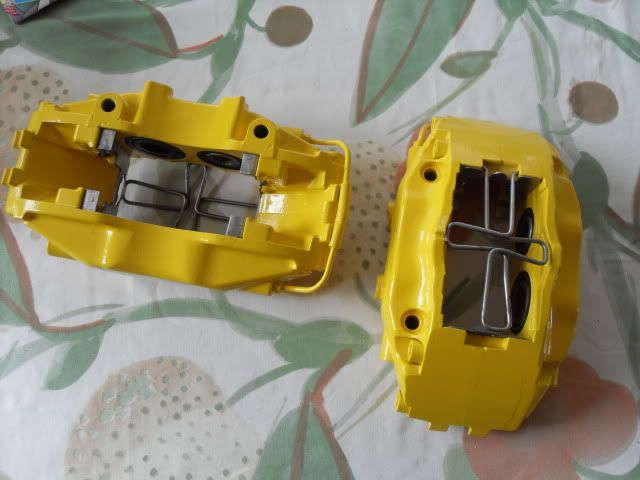

Hi all was just wondering if anyone has ever dealy with plate lift on their turbo/S2 calipers? In particular how did they remove the tiny screws holding the plates on. It look to me as though the plates themselves should be reuseable once the underlying corrosion has been dealt with. Was it a case of removing the heads from the screws then removing the shank afterwards? If not what tool did you use. Are they a standard allen screw or a torx screw? I can't quite make it out. Thanks in advance guys.