ORIGINAL: AndrewS

ORIGINAL: zcacogp

Ummm, why would this help? Given that the component giving concern is the torque tube, and this is between the engine and the gearbox, limiting the engine torque in any one gear won't help. It is subjected to the full torque output of the engine (at full throttle, naturally), no matter which gear the transmission is in ...ORIGINAL: AndrewS

... the plan is to program the PCM to limit the torque in specific gears at certain points to ensure that no component suffers any undue torsional stress when the throttle is mashed to the floor.

(Please feel free to correct me if I am missing something! [] )

Oli.

Hi Oli,

Best way to explain is as follows:

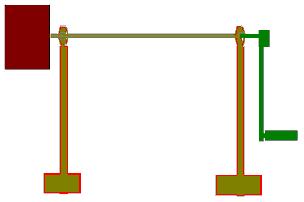

Imagine you have a wooden shaft with a handle at one end and a large heavy weight at the other end. The wooden shaft is supported at both ends by mounts and will turn freely (see picture)

If you violently turn the handle, the shaft may snap. If you turn it more gently and then gradually increase the speed and force with which you are turning it, the weight will turn and the speed of the weight turning will increase. When the weight is turning quickly and you increase the force at which you are turning the handle - the shaft will not be as stressed as if you attempt to turn it with great force when the weight was stationary.

This is the principle of torque management which can be achieved electronically.

Regards,

Andrew

That's a good simile Andrew. So this isn't a torque management tool based on sensors or 'live' information like a traction control, this is something that gets pre programmed into the 'ECU' so those limits are always pre set? So you mash the throttle and it will always respond in the same manner? Perhaps I'm simplifying this, but if that's the case I'm not sure that appeals 100%. However overall at 20k for what you describe, it sounds like a great deal. To what level is the rest of the car refurbished? New interior, paint, wheels etc?